DİSCOVER THE BENEFİTS OF METAL SPİNNİNG

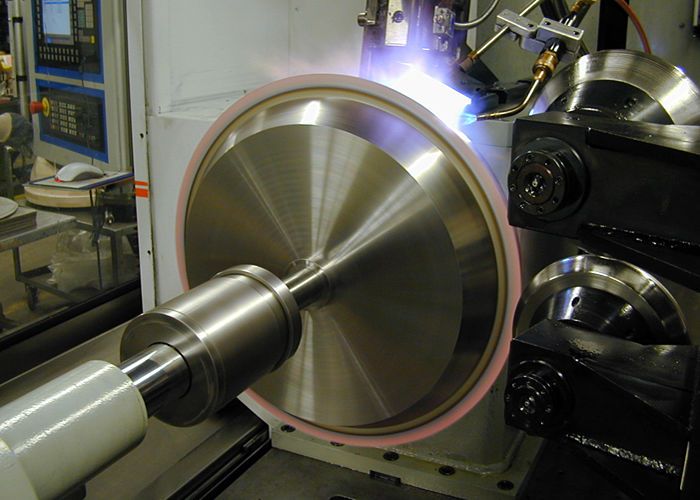

As organizations strive to operate with maximum efficiency, they look for more agile and versatile means to support their business objectives. Metal spinning has taken on new relevance as a proven technology for simplifying, streamlining, and reducing the expense of producing axially symmetric parts. Development of new, automatic spinning machines using CNC controls and playback technology allows high volume production of tight tolerance parts with consistent repeatability.

The process of metal spinning, also referred to as spin forming, is a metal working process that is used for producing metal objects that are round, cylindrical, or spherical in shape. In addition to improved structural integrity, metal spinning offers numerous advantages over other forming processes and allows you to achieve substantial cost savings through low-cost tooling, increased material yields, reduction or elimination of secondary operations,.

The spinning process can also accommodate any size and short lead times. Unmatched in terms of flexibility, metal spinning is well-suited for both prototyping and high volume production art — from small cylindrical caps to large diameter satellite dishes. All malleable metals can be used in this process. These include stainless steel (series 300 and 400), carbon steels, aluminum (2000 series, 3000 series, 5000 series and 6000 series), copper, bronze, brass, inconel, hastelloy, and titanium.